How to Fill and Use a Grease Gun

Squeaking and other noises from the suspension system is often a sign of joints or components that need grease, and failing to service these parts promptly can lead to permanent damage or failure. Having a grease gun and knowing how to use it can help you make quick work of this maintenance task to keep your vehicle driving at its best. Learn more about how to load a grease gun, as well as how to use your new grease gun, with our informational video, or follow the step-by-step instructions below.

Tools & Materials

Instructions on Filling and Using a Grease Gun

Grease guns are essential for vehicle chassis and suspension service, and allow users to easily grease ball joints, tie rods, control arm bushings, and more to extend their life. A grease gun is designed to securely couple with a Zerk fitting on your suspension component to allow grease to pass between the gun and the component. Grease guns must be filled with grease before use, either by loading the grease gun with grease from a container or using a grease cartridge. Setting up and loading your grease gun properly can help ensure a successful suspension service.

How to Prepare and Use a Grease Gun (with a Grease Cartridge)

Step 1: Open Your Grease Gun

Step 2: Insert Your Grease Cartridge

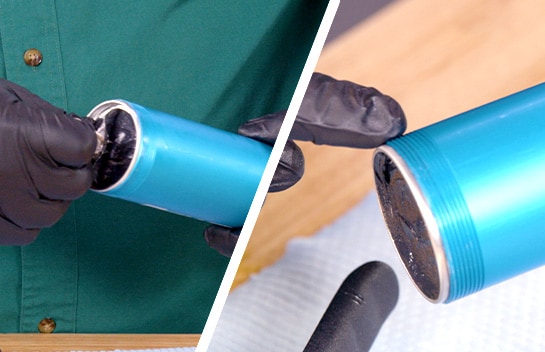

Step 3: Reinstall Your Grease Gun Barrel

Step 4: Push Your Grease Gun’s Inner Rod

Step 5: Depress Your Grease Gun Air Bleeder

Step 6: Attach Coupler to Grease Gun

How to Prepare and Use a Grease Gun with a Grease Container

Step 7: Submerge Your Grease Cylinder

Step 8: Load Your Grease

Step 9: Reattach Your Grease Gun Head

Step 10: Prime Your Grease Gun

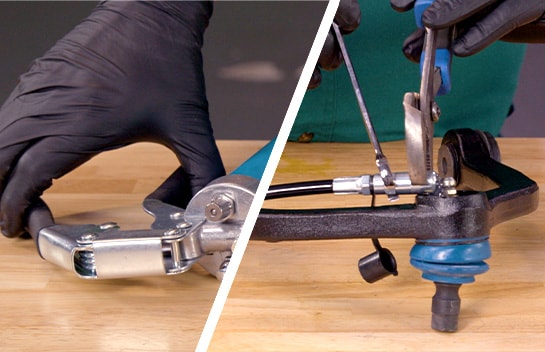

Step 11: Adjust Your Coupler for a Zerk Fitting

Step 12: Pump Grease into the Zerk Fitting

Step 13: Remove Coupler from Assembly

Additional Resources

The automotive repair work depicted in this series is performed under the direction of the manufacturer of the product featured. Prior to undertaking any of the demonstrated repairs on your vehicle, we suggest you consult with a certified mechanic or another professional who can adequately advise you of the proper repair or remedy required. O’Reilly Automotive Stores, Inc. and its affiliates (“O’Reilly”) disclaims any responsibility for injury or damage resulting from a viewer’s attempt to recreate the repairs shown in this series.

Safety Glasses

Safety Glasses

Nitrile Gloves

Nitrile Gloves

Grease Guns

Grease Guns

Grease Cartridges

Grease Cartridges

Grease Containers

Grease Containers

Control Arm and Ball Joint Assemblies

Control Arm and Ball Joint Assemblies

Shop Towels

Shop Towels